BST-FA

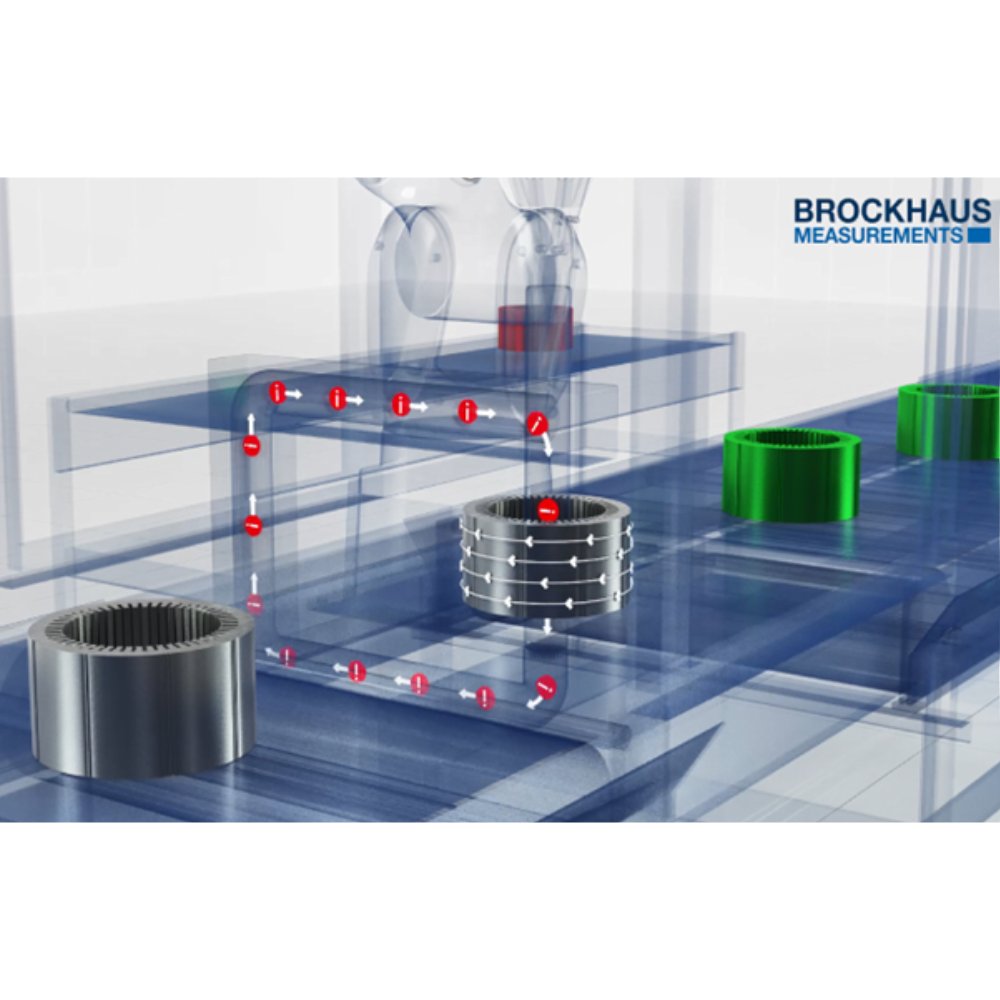

- Fully automated Stator Tester

- 100% quality check in production line

- Short cycle time

- Relative magnetic properties of the tested stator

- High repetitive accuracy

- BROCKHAUS® MPG Expert software for measurement, presentation and integration into QM systems

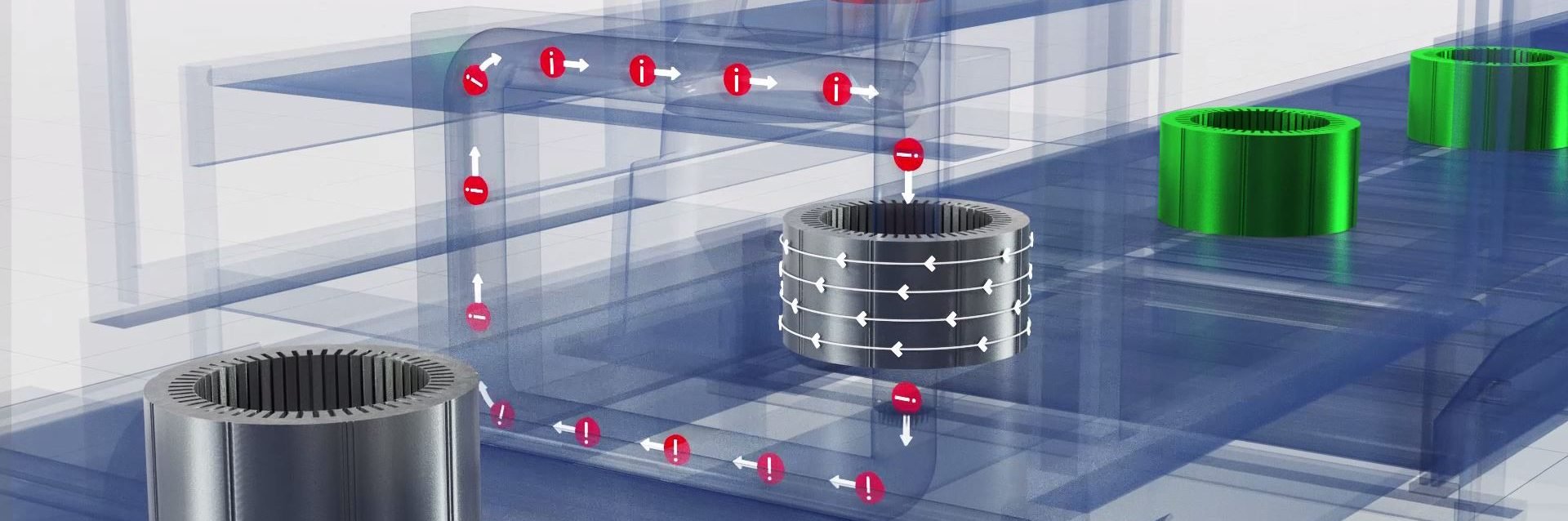

Operating principle

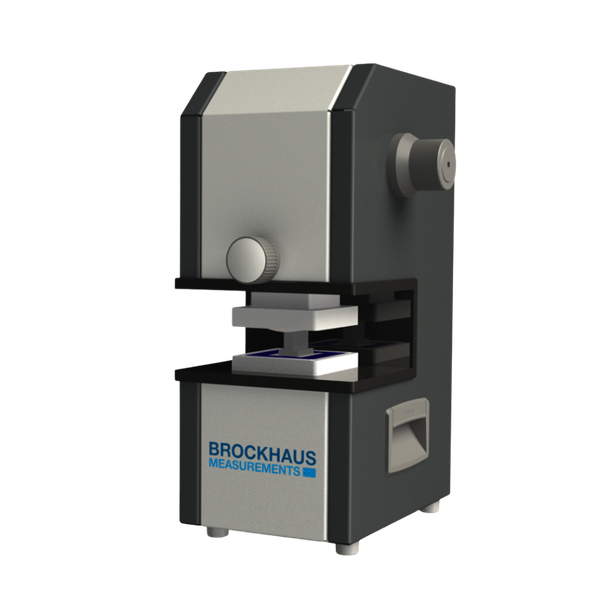

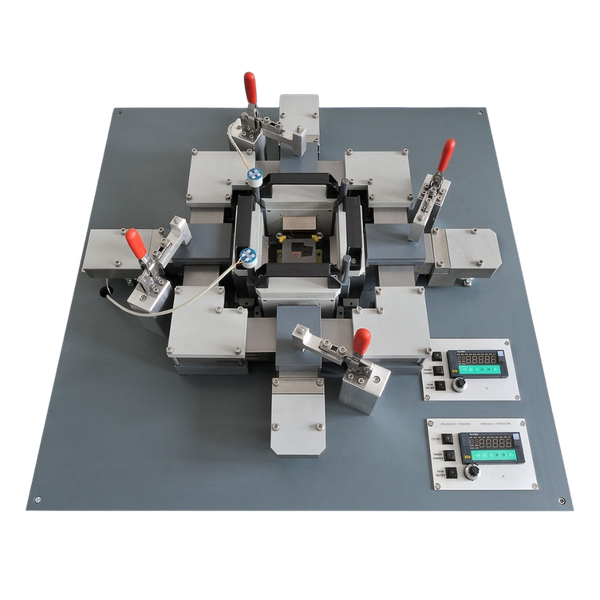

Automated measurement system measures stator and rotor stacks of defined size and allows a 100% testing in an automated production line. The software compares the measured results with a reference value and bad stacks can be sorted out automatically. In general power loss and/or permeability are measured at a certain working point (polarization value). Measuring cycle takes 3 to 15 seconds.

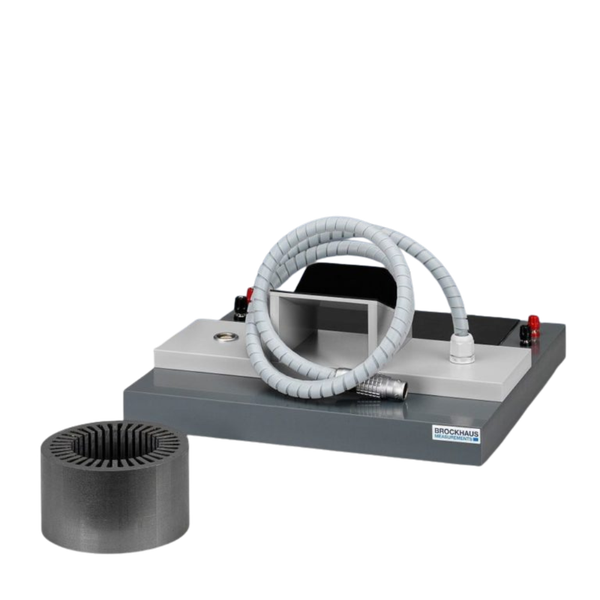

Stator and Rotor core sensor to measure magnetic properties on defined test specimen for 100% quality check. The sensor is to be connected to the measuring system MPG 200D-BST-FA. The stator stack will be positioned by a handling system (not part of supply) into the correct measuring position. Then a u-shaped bracket with primary (excitation) and secondary (sensing) windings moves into the stator and makes contact with the opposite side. Measurement starts automatically.

| Measuring frequencies: | 3 Hz to 20 kHz |

| Field strength: | selectable 1 A/m up to 5000 A/m |

| Polarization: | 1 mT up to 2 T |

| Adjustment precision: | better than 0.2% |

| Repeatability: | better than 0.3% |

| Cycle Time: | 3 to 15 seconds per Stator |

| Power supply: | 3 x 400 V AC, neutral, PE |

Measurement-as-a-Service

Instead of buying this product outright, you can also book the related service and enjoy all the benefits without the commitment.

Flexible

Convenient

Tailored to your needs