Application examples

Initial situation

During the shutdown of a hydrocracker unit, wastewater generated in the process was to be treated using a three-phase decanter.

The oil/water mixture was continuously transferred by vacuum trucks into five mobile storage tanks arranged next to the decanter.

After separating the sediments and the water phase, the oil phase was temporarily stored in another tank, from which vacuum trucks took over disposal.

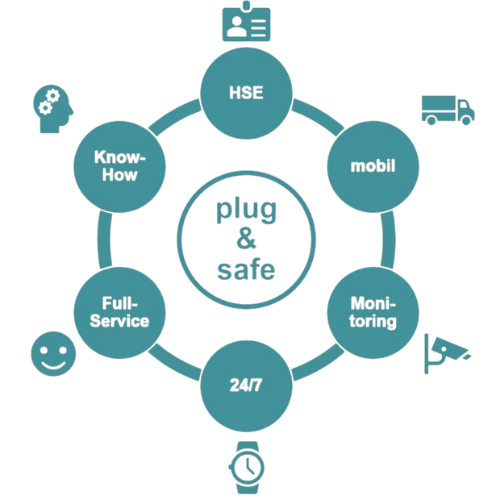

To ensure TA-Luft-compliant ventilation, our client requested a complete solution for the exhaust-air purification of the mobile storage tanks.

In addition, a level monitoring system was required to prevent overfilling of the tanks.

As the shutdown progressed, further wastewater treatment was also to be implemented in order to reduce the load on the on-site wastewater treatment plant.

Application examples

Solution

Application examples

Result

By using the BROCKHAUS exhaust-air purification system, TA-Luft-compliant ventilation of the mobile tanks was successfully ensured.

Hydrocarbon concentrations ranging from 300 to almost 5,000 ppm were adsorptively removed.

In addition to verifying purification performance, the monitoring system ensured consistently safe and controlled operation.

The BROCKHAUS water activated carbon filter, added later in the shutdown process, further reduced the load on the on-site treatment plant.

In summary, thanks to close cooperation with all involved partners, the project was completed on schedule and in an environmentally friendly manner.