Application examples

Initial situation

Kerosene contamination occurred in the tank farm of a refinery and was to be remediated using three extraction wells.

The treatment system was designed for a maximum flow rate of 100 m³/h and an operating pressure of up to 5 bar.

The objective was to permanently reduce the hydrocarbon concentration in accordance with the discharge specifications.

The following limit values applied:

- BTEX < 50 µg/L

- Benzene < 10 µg/L

- Trimethylbenzene < 50 µg/L

- Naphthalene < 2 µg/L

After commissioning, however, difficulties arose due to fluctuating influent concentrations.

In particular, the increasing iron content led to the formation of iron hydroxide sludge, which accumulated in the activated carbon filters.

These deposits caused clogging, resulting in higher pressure and a significant reduction in flow rate — down to around 25 m³/h.

Application examples

Solution

Application examples

Result

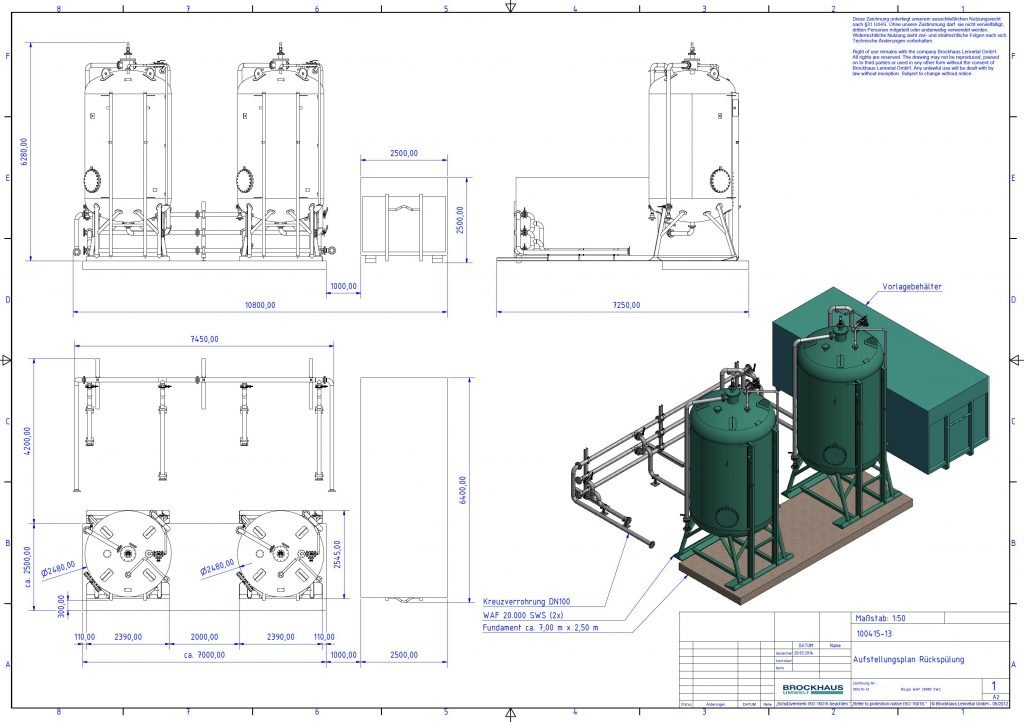

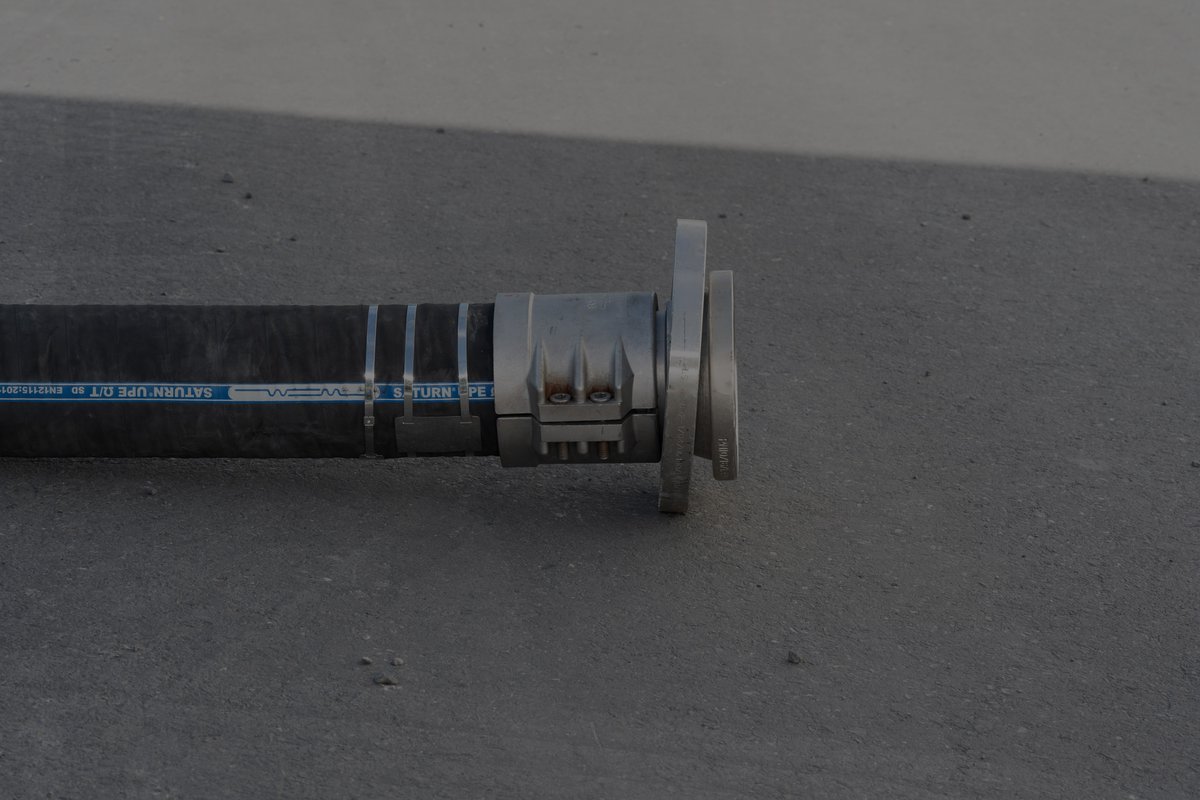

To address the challenge that arose after commissioning, a new cross-piping system and an additional storage tank were installed.

With the upgraded equipment and control system, the filters can now be backwashed efficiently.

This allows the iron hydroxide sludge to be flushed back from the activated carbon filters into the storage tank, preventing clogging and pressure build-up.

The filters are now backwashed three times a day, supported by differential pressure monitoring.

These measures have established a stable process that has continuously met the discharge specifications since 2014.